Rockwool Insulation

Rockwool Insulation Batts

Rockwool is a mineral wool insulation made from recycled steel slag (a byproduct of steel production) and natural rock such as basalt, limestone, or diabase. Mineral wool manufactured primarily from steel slag is also referred to as slag wool.

Rockwool Performance:

Rockwool insulation has typical R-values of between 2.8 to 3.7 per inch.

There are three primary forms of mineral or rockwool insulation, blown-in, batt insulation, and rigid foam board insulation. Let's take a look at what each type can offer your green home.

Blown-In Rockwool Insulation:

Blown-in rockwool insulation can be used in either enclosed cavities such as walls or unenclosed spaces like attics. Blown-in rockwall insulation resists settling, which can decrease an insulations' R-value over time.

For wall cavities in existing homes, it is installed by drilling small holes between the exterior walls' framing studs and blowing it in with special equipment.

For open attic ceiling installation, a 2' x 2' opening into the attic is typically all that is required for installation.

Blown-in rockwool insulation installation is usually done by professionals who are experienced at operating the necessary special equipment and can also ensure proper density and complete coverage.

Whether you install blown-in rockwool insulation yourself or pay somebody to do it for you, make sure to avoid voids and gaps which can occur if insulation is installed at too low a density or if a cavity isn't completely filled.

Rockwool Batt Insulation

Batt-Type Rockwool Insulation:

Batt is short for batting, which is a slab-shaped piece of rockwool insulation typically sold in rolls. Rockwool insulation batts can be used in unenclosed attics simply by placing them between the ceiling joints of your house. Batts are rectangular pieces 4 by 8 feet in size and are manually placed one by one until the floor of your attic space is covered completely.

Batts can also be placed in wall cavities between the framing studs during construction of your home prior to the installation of the drywall. While blown-in insulation is typically installed much quicker, batt insulation can be a better choice if doing the installation yourself. It is also much easier to remove from an attic space in the future if necessary. Rockwool batt insulation products spring back after compression during installation so that the installed performance is maintained over the lifetime of the product and the potential for gaps and spaces is reduced.

Like blown-in insulation, care should be taken that the rockwool batts are installed properly with no gaps or spaces in order to maximize the energy savings potential of any insulation.

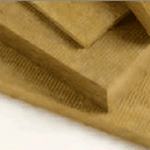

Rockwool Insulation Board

Rigid Board Rockwool Insulation:

Rockwool fibers can also be manufactured into a rigid boardstock insulation. Unlike blow-in or batt insulation, boardstock insulation is applied directly to the interior or exterior surface. This is an excellent choice for foundation insulation. Heat loss from an uninsulated basement foundation can represent up to 50% of a home's total heat loss in an otherwise well-insulated home.

In addition to reducing heating costs, rigid rockwool boardstock insulation reduces the potential for condensation because the mineral fibers will not absorb moisture or support the growth of mildew and fungus. It also will not rot or decay.

Green Qualifications of Rockwool Insulation:

Due to its use of natural and recycled materials, rockwool insulation can be a excellent addition to a green home design. Its manufacture does not use CFC or HCFC gases